- You are here:

- Home »

- Blog »

- Saws

- » Miter Saws Vs Table Saws

Miter Saws Vs Table Saws

There is no greater age old debate as to which is better; the Miter Saw or the Table Saw. Here today, we will be trying to address this debate and hope to finally bring it to an end, once and for all.

Why is there Such a Debate About These Two Saws?

Be it over precision and accuracy, or quality and quantity, many a work site has had its fair share of rowdy debates as to which is the superior saw.

Both sides have their advantages and disadvantages over one another. Some people flat-out refuse to acknowledge the existence of the other saw, others will stand there mocking the other for their perceived weaknesses.

In truth, its all just a lot of hot air.

Both saws have their place on the work site. Both have their advantages, and there are undoubtedly benefits to using one over the other for various tasks.

The cause of the debate, comes down to nothing more than personal preference. A true craftsman would actually embrace both of these saws, and see the benefits they both have to offer.

All jokes aside, in this article we will be going over what both types of saws can do, and offer our own personal take on which saw would be better suited for which job.

What are Miter and Table Saws?

Both saws use a circle blade that rips into material by spinning the blade in a continues motion. This is unlike reciprocating saws and hand saws, that use a back and forth motion to cut through materials.

The main difference between a miter saw a table saw, is in the way that they are designed to have the blade and material meet. A miter saw, also known as a drop saw, is designed to have the blade brought down onto the material. A table saw on the other hand, is designed to have the material brought to the blade.

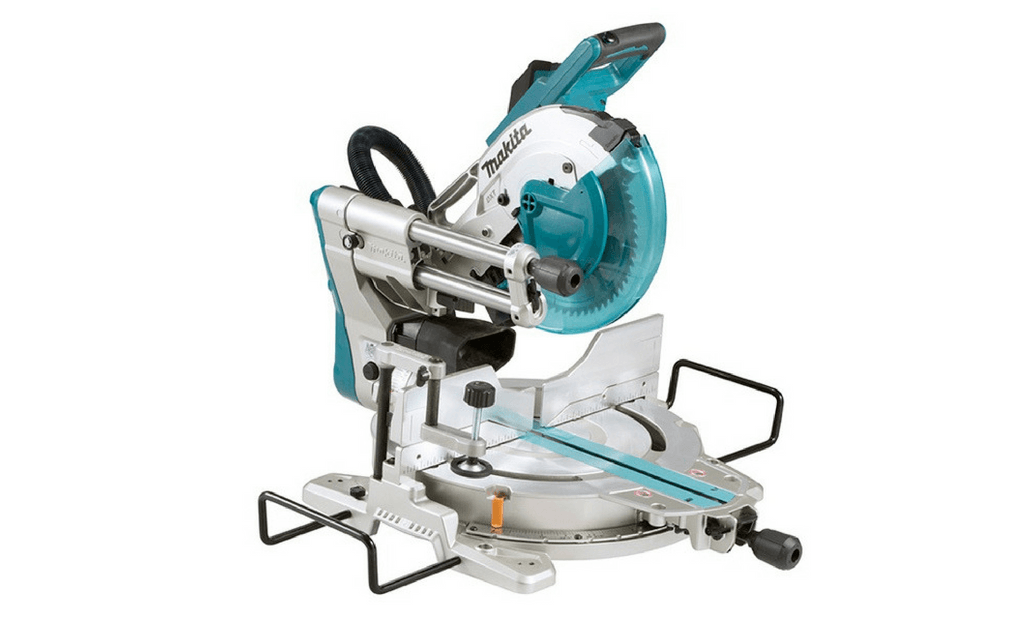

What is a Miter Saw?

A miter saw basically consists of a hinged radial arm bar and a blade. Miter saws are designed to have the operator grip pull down handle, and to bring the rotating blade down onto the material to be cut.

Some are designed with the main on/off switch controlling when the blade spins. Others use a pull trigger to active the blade or to release the arm. As long as the pull trigger is activated, the blade continues to spin, only shutting off when the trigger is released.

A safety latch may also catch the arm bar when it returns to its upright resting position when the trigger is released. As part of a safety feature, most modern miter saws will not allow the arm to be lowered unless a release trigger is pressed.

For our review on the top 5 miter saws, please read our article here.

What is a Table Saw?

A table saw is simply a flat table with a saw blade that protrudes up, out of the center of the table. The depth of the cut can be determined by how high the blade sticks up out of the table. They are also designed to have the materials brought to the cutting blade, not the other way around.

Like the miter saw, some table saws have an on off switch that controls the blade. Other saws may use a foot peddle to active the blade while it is pressed down, and deactivates the blade once it is released.

For our review on the top 5 table saws, please read our article here.

How Do The Saws Operate

Both saws make use of stops and guide fencing to set the point where the blade meets the material. Guides are used to do simply that, guide the material to the appropriate cutting position. Stops are used to determine where the set length material will be cut off at or how far along the blade the material will travel.

How do Miter Saws Cut Into the Materials?

Depending on the model you are using, most miter saws have a back guard/ fence. This is used to hold the material in place as the saw blade is brought down on top of it.

Realistically, the blade isn’t cutting in a straight downward motion. The blade is actually being brought down in an arching motion, and cuts into the material at a point closer to the operator, than the actual center of the material’s thickness.

As a result, this can cause some materials to not be cut through completely. Sometimes a burr may be left on the lower back corner of the material has not been positioned against the back guard correctly. Additionally, if the material is much too thick to be cut in one clean motion, it can leave an uneven cut face when the material is rolled over to be cut from the other side.

How Do Table Saws Cut Into the Materials?

Table saws are designed to have adjustable fences. The fences are used to create a gap for the material to be passed through and cut at the desired dimensions.

This gap could be as wide as half the length of the table, longer with extended fence guides, or the fence could be brought within a fraction of an inch of the blade, and even completely removed from the table all together.

This makes the table saw ideal for ripping long cuts, or for cutting slots part way down into the material like you would with a jigsaw, band saw, or hand saw. The blade also have another benefit of being able to be adjusted from full protruding, to only partially sticking out above the table.

Best Uses for Each Saw

Put in the most simplistic way possible, miter saws are used to make short quick cuts, and to cut material to the desired lengths. While table saws are used to make long precise cuts, and to rip material into the required widths and thicknesses.

For example, a piece of 2×4, would be more suited to be cut to length on an appropriately sized miter saw. But it is better to reduce the thickness or width of the 2×4 by using a table saw.

The miter saw can cut the 2×4 at any length desired. Even if a stop could not be put in place, the operator could use a tape measure to make the correct spot to cut, and with the aid of the back guard, they could be guaranteed a perfectly square and flush cut.

On the other hand, the table saw could be used to cut channels down to whole length of the 2×4 for cabling, or shelving guides. Or it could be used to reduce the width or thickness of the 2×4 into something smaller.

Trying to cut a long length of 2×4, with or without the use of a fence, can be more tricky on a table saw then a miter saw. The margin of user error could result in a cut that’s not straight, or cause the timber to fling up and off the table once the saw blade begins to cut deep into it.

What Can Miter Saws Cut?

Here are a few examples of how a miter saw can be used, and the types of materials they can cut:

- Assuming that the miter saw has variable speed settings, it could be used to cut metal, aluminium, stone, timber and plastic. Different blades can be used at different speeds to cut the different types of material.

- They can also cut solid and thin material just as easily as hollow materials such as pipes and bamboo, and softer materials such as foam and aerated cement blocks like hebel.

- Additionally the material does not need to have a flat surface. By using a vice clamp, miter saws can be used to cut round materials to length.

- As the materials are brought through under the blade, it makes cutting full 24′ lengths of material an easy task to do.

- The blades can also be angled to cut up to 45° left and right. Depending on the model, this can be done by changing the position of the arm itself in relation to the base. Other models adjust the back guard instead, leaving the arm in its original position.

- In addition to the different materials and angels that miter saws can cut. They can also be used to cut multiple pieces all at once. By stacking or bundling the material, the saw blade can be brought down to cut the grouped material very easily. This makes the miter saw a very efficient tool for producing multiple pieces of the same length.

- They can also be used to make quick and rapid cuts, such as cutting up spacers and blocks, or for putting drainage slots into random places on PVC piping.

The biggest draw backs to using a miter saw are:

- They can only be used to make short cuts.

- The blade can not be used to make guide slots or channels.

- You may require additional supports, stands or a table to position the miter saw at a comfortable working height, as well as to hold the materials in place.

What Can a Table Saw Cut?

Table saws are designed for larger projects. Here are a few examples of the different types of material they can cut and the the various projects you could use them for.

- Table saws are great for ripping sheets of MDF, aluminum composite panels, and plastic into more manageable sizes.

- They can also be used to reduce the thickness of timber pieces, or to plain down the edge of a strip of wood that was only a faction too wide.

- Table saws can be used to cut a variety of flat materials or products. This makes them ideal for making boards out of panels more productively then by using a circular saw or a jigsaw.

- The long fence guide, makes the table saw perfect for cutting long strips, or for setting the blade into position to make a guide slot in the material.

- Not only can the height of the blade be adjusted to suit the task at hand, so to can its angle. The blade can be tilted back or forth, by up to 45°, producing some very clean miter cuts.

- They also come with their own work bench to support the materials.

The biggest draw backs to using a table saw is:

- They are not very good for cutting round materials such as bars, tubes, or pipes, however. As the the material needs to be guided into the blade, this can cause round materials to roll, and with the blade also pushing the material down, it can cause some materials to spin or kick back.

- Hollow material can be dented or cracked by the force of the blade.

- Trying to cut full 24′ lengths of material can be difficult to do with a table saw.

- While they can be used to cut material to length, the longer the length of the cut vs a narrower strip of material, the harder it is maintain a square cut. Experience can rectify this, but it takes a lot of practice to be able to tell if the material is being feed through at the correct angel.

Final Thoughts

When trying to decide whether or not you should favor one tool over the other, the first thing that really needs to be taken into consideration, is the type of material(s) you intend to cut.

The shape of the material, thickness, raw length, and intended end product, all require different things to be taken into consideration. Using the saw that best suits the individual tasks at hand will make the job much easier. For this reason, we would recommend that all work sites/shops have both saws available for use.